Innovator Stories

Growing up in Puerto Rico, Evaguel Rhysing discovered a love of space and technology watching reruns of NASA rocket launches. When her mother bought her a book series about space, she read all six volumes in two days. She watched her VHS copy of the moon landing anniversary special over and over again.

“I was obsessed with zero gravity,” she said. “People floating seemed like magic, like they had a super power.”

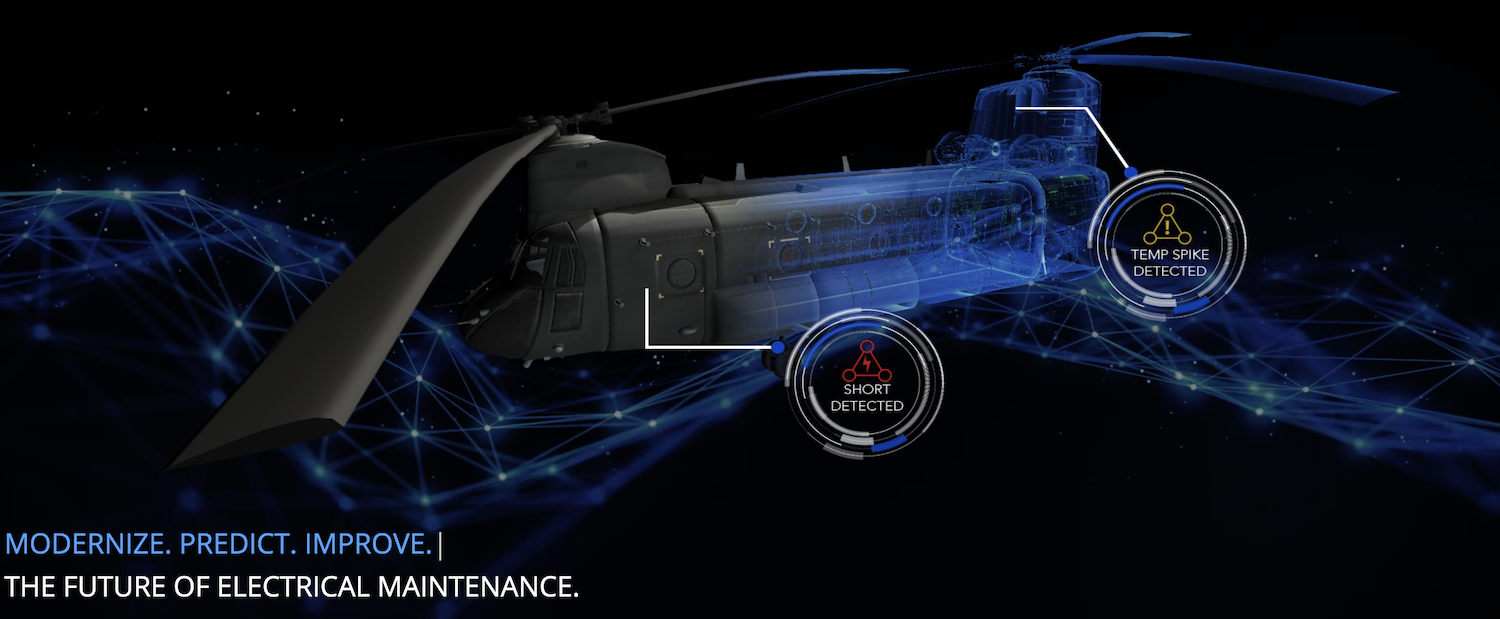

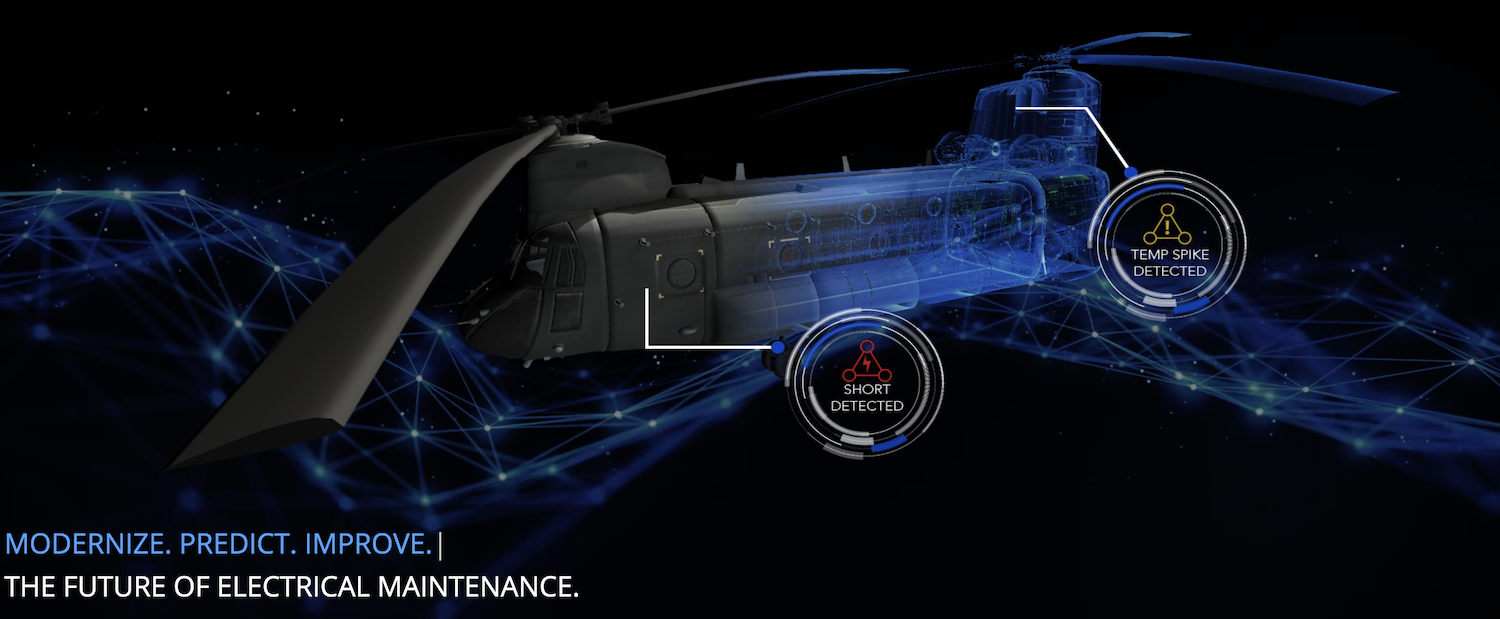

Now, Rhysing is the CEO of United Aircraft Technologies (UAT), which produces a clamp to hold electrical wires that has the potential to change an entire industry. “We’re replacing an antiquated metal clamp with a lightweight thermoplastic clamp that has sensors embedded to monitor performance,” she said. “Our clamps will revolutionize electrical system management.” It’s already passed bench testing for military specifications and has attracted contracts from the U.S. Army and Air Force.

Innovator Stories

Meet Evaguel and Daryian Rhysing

Growing up in Puerto Rico, Evaguel Rhysing discovered a love of space and technology watching reruns of NASA rocket launches. When her mother bought her a book series about space, she read all six volumes in two days. She watched her VHS copy of the moon landing anniversary special over and over again.

“I was obsessed with zero gravity,” she said. “People floating seemed like magic, like they had a super power.”

Now, Rhysing is the CEO of United Aircraft Technologies (UAT), which produces a clamp to hold electrical wires that has the potential to change an entire industry. “We’re replacing an antiquated metal clamp with a lightweight thermoplastic clamp that has sensors embedded to monitor performance,” she said. “Our clamps will revolutionize electrical system management.” It’s already passed bench testing for military specifications and has attracted contracts from the U.S. Army and Air Force.

Invented by UAT CTO and Executive Chairman Daryian Rhysing, the Interconnecting Clamp reduces weight and simplifies maintenance. Aircraft wiring clamps often number in the hundreds, and locating issues immediately with innovative technology can save time and improve safety. Daryian’s design incorporates augmented reality and artificial intelligence to aid troubleshooting. His system can identify issues with individual clamps or with specific wires in a bundle. Drawing on her love of space, Evaguel likens the technology to Star Trek’s computers being able to locate problems on the Enterprise .

Evaguel and Daryian Rhysing are married. Evaguel’s background in teaching, linguistics, and business makes her well-suited to lead UAT. Evaguel moved to New York state in 2007. There she met Daryian, an engineering student at RPI who had been forced to retire as an aircraft mechanic because of repetitive motion injury in his wrists, which he attributes to having installed tens of thousands of the traditional metal wiring clamps. His first clamp design was intended to solve the wrist injury problem by employing high-strength plastic with a clip-on installation. Then Daryian saw the opportunity to further refine his design for weight savings, safety, and ease of aircraft maintenance.

“Our life experiences equipped us to keep each other going in hard times”, Evaguel explained. We challenge each other to be our best, and we balance each other’s strengths. We have a deep respect for each others’ expertise.”

UAT started in 2017; seeking business development opportunities, Evaguel and Daryian entered and won Lever’s Berkshire Manufacturing Innovation Challenge in 2019. Lever later invested in UAT through its Pilot Fund, which makes strategic investments in regional companies with high growth potential. The company has gone on to receive awards from MassChallenge, Sikorsky, NASA iTech, and the U.S. ArmyxTechSearch, among others, as well as major contracts for its product.

UAT is moving its engineering team to Pittsfield, Mass., closer to some of its suppliers, and is working on an US Air Force Contract for their Agility Prime program as well as work for the Army’s Future Vertical Lift Initiative, which will develop new military helicopters–with UAT’s Interconnecting Clamps.

“Lever was the first group that believed in our capabilities,” Rhysing said. “After that, I was able to come on full-time as CEO, and we’ve been going strong ever since. Their guidance, and helping us realize our capabilities, gave us the confidence to pursue this work, to take chances, and to believe in ourselves.”

Invented by UAT CTO and Executive Chairman Daryian Rhysing, the Interconnecting Clamp reduces weight and simplifies maintenance. Aircraft wiring clamps often number in the hundreds, and locating issues immediately with innovative technology can save time and improve safety. Daryian’s design incorporates augmented reality and artificial intelligence to aid troubleshooting. His system can identify issues with individual clamps or with specific wires in a bundle. Drawing on her love of space, Evaguel likens the technology to Star Trek’s computers being able to locate problems on the Enterprise .

Evaguel and Daryian Rhysing are married. Evaguel’s background in teaching, linguistics, and business makes her well-suited to lead UAT. Evaguel moved to New York state in 2007. There she met Daryian, an engineering student at RPI who had been forced to retire as an aircraft mechanic because of repetitive motion injury in his wrists, which he attributes to having installed tens of thousands of the traditional metal wiring clamps. His first clamp design was intended to solve the wrist injury problem by employing high-strength plastic with a clip-on installation. Then Daryian saw the opportunity to further refine his design for weight savings, safety, and ease of aircraft maintenance.

“Our life experiences equipped us to keep each other going in hard times”, Evaguel explained. We challenge each other to be our best, and we balance each other’s strengths. We have a deep respect for each others’ expertise.”

UAT started in 2017; seeking business development opportunities, Evaguel and Daryian entered and won Lever’s Berkshire Manufacturing Innovation Challenge in 2019. Lever later invested in UAT through its Pilot Fund, which makes strategic investments in regional companies with high growth potential. The company has gone on to receive awards from MassChallenge, Sikorsky, NASA iTech, and the U.S. ArmyxTechSearch, among others, as well as major contracts for its product.

UAT is moving its engineering team to Pittsfield, Mass., closer to some of its suppliers, and is working on an US Air Force Contract for their Agility Prime program as well as work for the Army’s Future Vertical Lift Initiative, which will develop new military helicopters–with UAT’s Interconnecting Clamps.

“Lever was the first group that believed in our capabilities,” Rhysing said. “After that, I was able to come on full-time as CEO, and we’ve been going strong ever since. Their guidance, and helping us realize our capabilities, gave us the confidence to pursue this work, to take chances, and to believe in ourselves.”