Contollo began in April 2020 as a “crazy” plan to supply hospitals with PPE amidst COVID shortages. CEO Peter Berzin explains that Norb Jankowski, a former engineer at a Franklin, Mass. die-cutting facility, formed the idea that became Contollo. Although the factory had been shuttered for years, Jankowski suspected the cutting machines were still present and could be repurposed to make PPE.

Jankowski contacted Franklin town council member Tom Mercer and Massachusetts State Representative Jeff Roy. With their help, Berzin and Jankowski determined that the die-cutting machines were functional, the factory was empty, and that its owners were willing to lease. Production began a few weeks later.

Contollo creates PPE gowns for medical institutions. Staff developed an innovative two-seam gown design, a new heat-sealing station method, and a material layering pattern. These advancements have allowed Contollo to produce 100,000 gowns per week, each with a four-use lifespan The company also makes disposable gowns that meet all FDA testing guidelines. The cost savings associated with Contollo gowns helped the company secure several large contracts. Contollo has also donated more than a thousand gowns to local hospitals and fire departments.

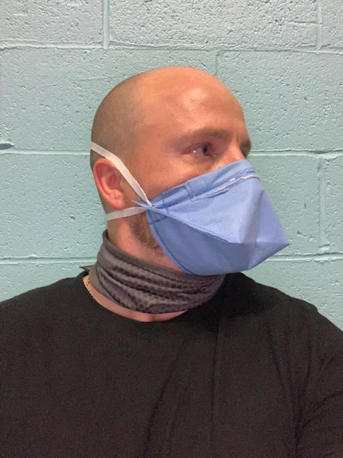

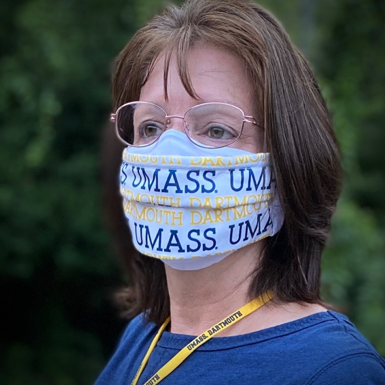

Berzin has even bigger plans for Contollo. With automation and further innovation, his goal is to produce 60,000 gowns per machine per day. He plans to repair the plant’s second die-cutter, expand operations into a new Franklin facility, and fabricate new PPE products such as face shields, respirators, and masks. Berzin plans to create “the safest, most comfortable, lowest-cost mask in the United States,” using only U.S. materials.

Despite its brief tenure in Franklin, Contollo has become deeply rooted in the town. Berzin said that the Franklin community “nurtured Contollo with relationships, feeding us support and encouragement.” In turn, Contollo’s growth will mean more jobs for Franklin residents.

Despite living in Pennsylvania, Berzin commutes to Franklin each week. He said that his friends think he’s nuts, but he bears little regret. “In PA, You don’t get the level of encouragement and energy coming from the town of Franklin.”